Top-Down Fire Method: Burn Smarter, Not Harder

The top down fire method represents a revolutionary approach to building fires that challenges traditional fire-starting techniques. Unlike conventional bottom-up methods where kindling and small materials are placed at the base, this innovative technique involves stacking larger logs at the bottom and progressively smaller materials toward the top, with ignition occurring from the uppermost layer.

This counterintuitive approach has gained tremendous popularity among wood stove enthusiasts, fireplace users, and camping aficionados for its superior efficiency and cleaner burn characteristics. The method promises reduced smoke production, longer burn times, and minimal maintenance, making it an ideal choice for anyone seeking to maximise the performance of their kiln dried logs while creating a more enjoyable and sustainable fire experience.

Key Characteristics of the Top Down Fire Method

The top down fire method distinguishes itself through several fundamental characteristics that set it apart from traditional fire-building approaches. The primary feature involves the strategic stacking order, where the largest logs form the foundation, followed by progressively smaller pieces, with kindling and firelighters positioned at the very top. This arrangement creates optimal airflow dynamics, allowing oxygen to circulate efficiently through the entire fuel stack while the fire burns downward in a controlled manner.

The benefits of this method are substantial and scientifically proven. Reduced smoke production occurs because the fire burns at higher temperatures from the onset, ensuring more complete combustion of volatile compounds that would otherwise escape as smoke. The longer burn time results from the methodical way the fire consumes fuel, with each layer providing sustained heat to ignite the next level below. Cleaner combustion means fewer particulates and reduced creosote buildup in chimneys, contributing to both environmental benefits and improved safety.

The physics behind this method can be understood through a simple analogy: imagine a candle burning down through layers of wax. Each layer provides fuel for the next while maintaining consistent heat output. Similarly, the top down method creates a self-sustaining system where each burning layer pre-heats and dries the wood below, ensuring optimal conditions for continued combustion. This approach is particularly effective with high-quality kiln dried logs, which have consistent moisture content and burn characteristics that complement this methodical burning pattern.

Comparison Between Top Down and Traditional Fire Methods

Traditional bottom-up fire building methods have been used for generations, involving the placement of tinder and kindling at the base, with larger logs stacked above. While familiar, this approach often results in several common issues including excessive initial smoke production, uneven burning patterns, and the need for frequent intervention to maintain the fire. The bottom-up method can create a "chimney effect" where flames race upward too quickly, leaving lower logs partially burned and requiring constant repositioning.

The top down method addresses these shortcomings systematically. Where traditional methods produce significant smoke during the initial lighting phase, the top down approach minimises smoke by achieving complete combustion from the start. Traditional fires often require multiple rounds of kindling and constant attention, while the top down method provides steady, self-regulating burn that can last several hours without intervention.

Comparison Summary:

|

Aspect |

Top Down Method |

Traditional Method |

|

Ignition Ease |

Moderate learning curve |

Familiar and intuitive |

|

Smoke Production |

Minimal throughout burn |

Heavy initially, reduces over time |

|

Burn Duration |

4-8 hours consistent |

2-4 hours, requires reloading |

|

Safety |

Self-contained, stable |

Requires frequent monitoring |

|

Maintenance |

Minimal intervention needed |

Regular tending required |

The top down method proves superior in most residential heating scenarios, particularly when using premium kiln dried logs that burn predictably and efficiently. However, traditional methods may still be preferred for quick heating needs or when working with mixed-quality wood that requires more hands-on management.

How to Build a Fire Using the Top Down Method

Successfully implementing the top down fire method requires careful preparation and attention to detail. The essential materials include various sizes of kiln dried logs ranging from large split pieces (4-6 inches diameter) to medium logs (2-3 inches), along with kindling, dry tinder, and reliable firelighters. The moisture content of your wood is crucial – kiln dried logs with less than 20% moisture content perform optimally for this method.

Step-by-Step Construction Process:

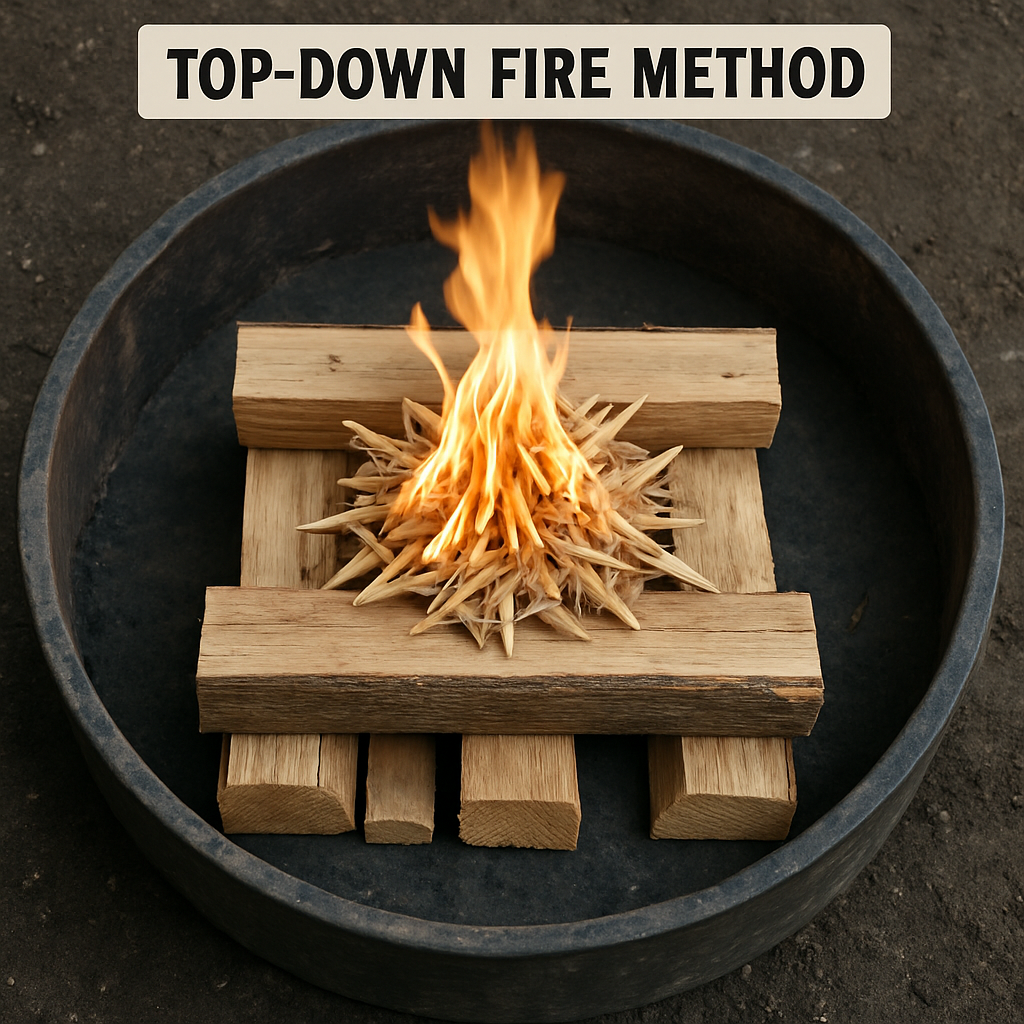

• Step 1 - Foundation Layer: Place the largest logs parallel to each other at the bottom of your firebox, leaving approximately one inch of space between each log to allow airflow. These foundation logs should span most of the width of your firebox and will serve as the base for your entire fire structure.

• Step 2 - Second Layer: Add medium-sized logs placed perpendicular to the bottom layer, again maintaining proper spacing for air circulation. This creates the cross-hatch pattern essential for proper airflow.

• Step 3 - Progressive Layers: Continue building upward with progressively smaller pieces, alternating the direction of each layer to create a stable, well-ventilated structure. Each successive layer should be smaller in diameter than the one below, creating a pyramid-like formation.

• Step 4 - Top Platform: Once you reach the top, create a platform of the smallest split wood pieces, then place your kindling in a loose, bird's nest pattern that allows plenty of air circulation.

• Step 5 - Firelighter Placement: Position your firelighters strategically within the kindling layer, ensuring they have contact with multiple pieces of small wood for reliable ignition.

• Step 6 - Ignition Process: Light the firelighters and allow the fire to establish itself in the top layer before closing any air controls. The key to success lies in patience – resist the urge to interfere with the natural burning process as the fire works its way downward through each carefully constructed layer.

Critical Success Factors:

Proper airflow management is essential throughout the burning process. Ensure your dampers and air controls are fully open during the initial lighting phase, then gradually reduce air supply as the fire becomes established. The spacing between logs in each layer must allow oxygen to reach all burning surfaces while preventing the structure from becoming unstable. When using kiln dried logs, their consistent burn characteristics make this method particularly reliable, as each piece will ignite and burn at predictable rates.

Practical Considerations and Troubleshooting

Despite its many advantages, the top down fire method can present certain challenges, particularly for newcomers to the technique. The most common issue involves fires that fail to catch properly, often resulting from inadequate kindling preparation or insufficient air supply. When the fire struggles to establish, check that your kindling is dry and small enough to ignite easily from your firelighters, and ensure adequate spacing between pieces for oxygen circulation.

Excessive smoke production, while less common with this method, typically indicates poor-quality wood or inadequate air supply. Using premium kiln dried logs eliminates moisture-related smoke issues, while ensuring your air controls remain fully open during ignition prevents oxygen starvation. If logs collapse prematurely, the structure may have been built too loosely or with inadequately sized pieces for each layer.

Temperature management requires understanding your specific heating appliance and adjusting the method accordingly. Wood stoves with limited height may require modifications to the traditional pyramid structure, while open fireplaces benefit from slightly closer log spacing to maintain higher burning temperatures. The method works exceptionally well with modern, efficient wood stoves that can capture and utilise the complete combustion this technique provides.

Expert Optimisation Strategies:

Experienced users often supplement the basic method with techniques such as creating "air channels" using small pieces of kindling placed strategically between larger logs, or incorporating different wood species to control burn rates. Hardwood kiln dried logs provide longer burn times and higher heat output, making them ideal for the foundation layers, while softer woods can be used in upper layers for easier ignition and faster establishment of the fire.

About Kiln Dried Logs Halifax

At Kiln Dried Logs Halifax, we specialise in premium quality kiln dried logs with moisture content below 20%, perfect for the top down fire method. Our family-owned business offers sustainably sourced hardwood and softwood logs including oak, ash, beech, birch, and spruce. We provide reliable delivery services across Halifax and surrounding areas, ensuring you receive the highest quality fuel for optimal fire performance and maximum heat output.

Top Down Fire Method - A Superior Choice

The top down fire method represents a significant advancement in fire building technology, offering measurable improvements in efficiency, cleanliness, and convenience over traditional approaches. Its ability to provide consistent, long-lasting heat with minimal smoke production makes it particularly valuable for modern heating needs and environmental consciousness. The method's compatibility with high-quality kiln dried logs creates an optimal combination that maximises both performance and value from your fuel investment.

The scientific principles underlying this technique – controlled combustion, optimal airflow, and systematic fuel consumption – result in more complete burning and reduced waste. For homeowners seeking to reduce their environmental impact while improving their heating efficiency, the top down method offers a practical solution that requires minimal additional investment beyond learning the proper technique.

We encourage readers to experiment with this method using quality kiln dried logs and observe the dramatic improvements in their fire experience. Share your experiences, challenges, and successes as you master this superior fire-building technique that truly allows you to burn smarter, not harder.

Frequently Asked Questions (FAQs)

Is the top down fire method suitable for all wood stoves?

Yes, the method works with virtually all wood stoves, fireplaces, and outdoor fire applications, though minor adjustments may be needed for specific appliance dimensions.

What distinguishes the top down method from other fire building techniques?

The key difference is lighting from the top and allowing the fire to burn downward through progressively larger fuel, creating cleaner combustion and longer burn times.

Which types of wood are best for the top down method?

Kiln dried logs with consistent moisture content below 20% work optimally, with hardwoods like oak, ash, and beech providing the best results for foundation layers.

How does the top down method compare to kindling cradle or other techniques?

Unlike kindling cradles that require bottom ignition and frequent tending, the top down method is self-sustaining and produces significantly less smoke with longer burn duration.

Can I mix different wood types when using this method?

Absolutely – using harder kiln dried logs for the base layers and softer woods for upper layers can optimise both ignition success and overall burn performance.

Share